Our global manufacturing footprint provides responsive, cost-effective, and high-quality production and distribution

Manufacturing

We begin every OEM project by identifying your needs, working from “the customer back” and taking a total cost of ownership approach. This includes developing and proposing the most optimal supply chain model to establish a lead time, minimum order quantity to maximize responsiveness and control costs. Our engineering and manufacturing teams are available to quickly take a new program from early concept to mass production.

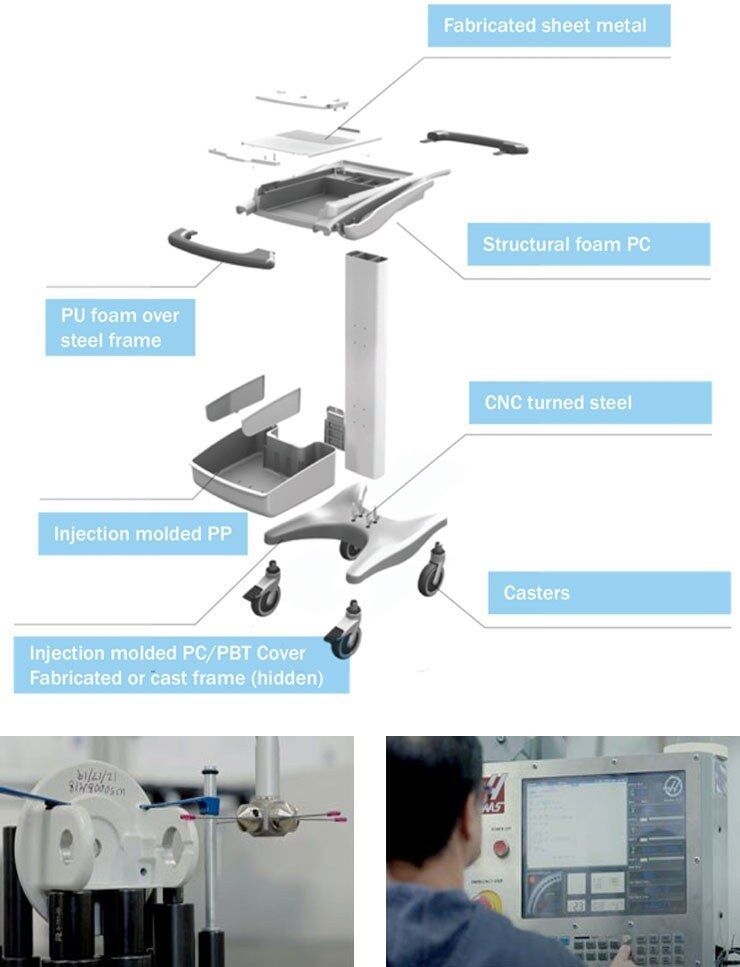

Our Quality Management System is ISO 13485 and 9001:2008 certified. The manufacturing processes that we leverage include:

- CNC milling and turning

- sheet metal fabrication

- aluminum extrusions

- injection molding

- die-cast aluminum and zinc

- wire form

- structural foam

- sand casting

- gravity-cast aluminum

- vacuum forming

- assembly

- machining

- finishing